Cacao

Precious Raw Material – much-loved Indulgence

Cacao is a valuable raw ingredient which Felchlin uses to produce one of the world's most popular luxury foods: exquisite Swiss couverture. Thanks to their individual environments, different countries of origin produce cocoa beans with multi-layered and intense flavours.

Regions of originTransparency and Fairness

The same applies to all regions from which Felchlin sources its cacao beans: transparency and a fair approach to local partners as well as the highest quality standards in the procurement of raw ingredients – ranging from careful harvesting to safe transport to the company's location in central Switzerland.

Cacao Tree

The cacao tree grows in various regions along the equator, where it benefits from an average temperature of around 25 degrees. A humid, rainy climate and the shade of larger trees encourage cacao fruit to grow.

Harvesting

Harvesting begins at the end of the rainy season, after the fruit has ripened. Farmers carefully remove the fruit from the trees using sharp knives without damaging the tree trunk, unripe fruit or blossoms. Harvested fruit is then split open and the beans and pulp are removed.

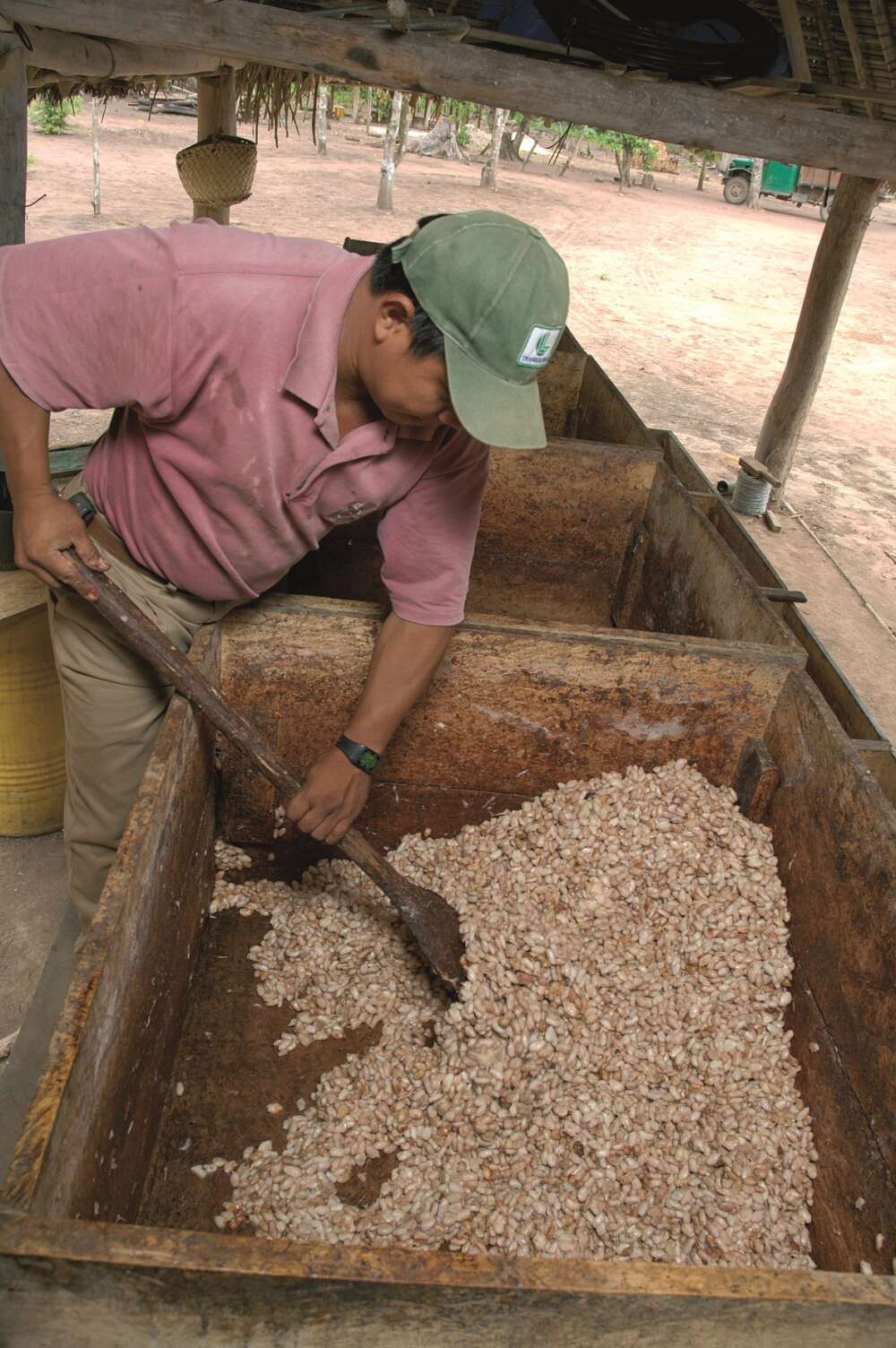

Fermentation

The beans and pulp are placed in a wooden crate and covered with leaves. Due to the high sugar content the mass begins to ferment and undesirable acetic acid vaporises. The fermentation process takes between five and seven days, during which the beans are regularly mixed to ensure a uniform fermentation.

Sun Drying

The farmer empties the wooden crates after fermentation is complete and spreads the beans out in the sun to dry. After five to ten days, the natural drying process is complete. A cutting test is then carried out. The beans are cut open and checked for moisture. The moisture content of the beans must not exceed 6% so as to prevent the formation of mould.

Selection and Transportation

The beans are then sorted according to size and quality, either by hand or using the simplest sorting equipment. This step is extremely important, as the beans should be as even as possible in terms of size for downstream stages of processing. The sorted beans are then filled into either jute or specially designed plastic bags. They are now ready for transport by shipping container to Europe.

«We live with passion and responsibility to bring enjoyment from the origin around the world.»

Professional area

Professional area